1.resin anụ ụlọokwu mmeghe

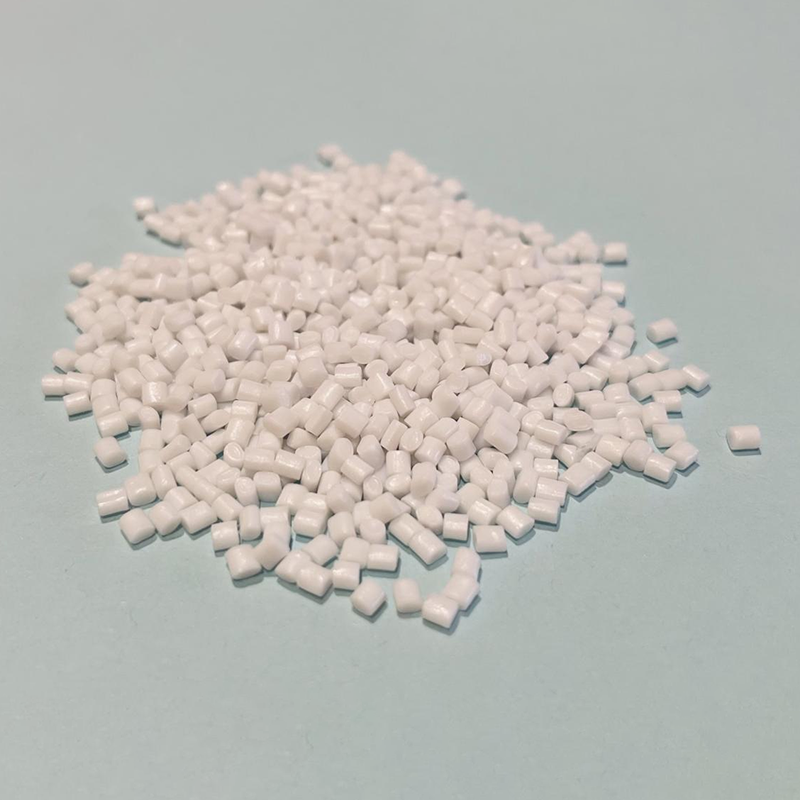

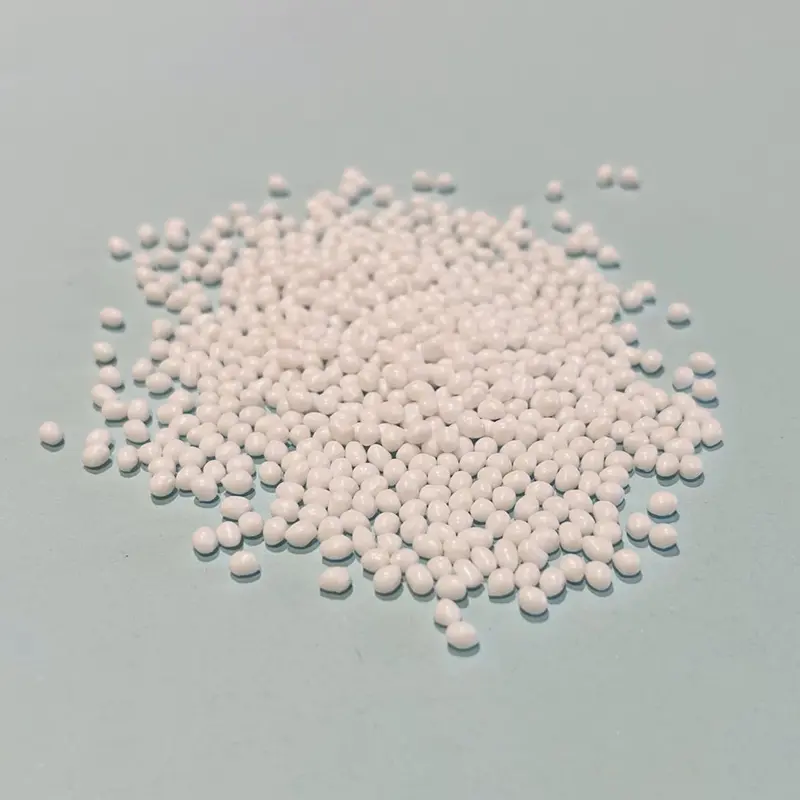

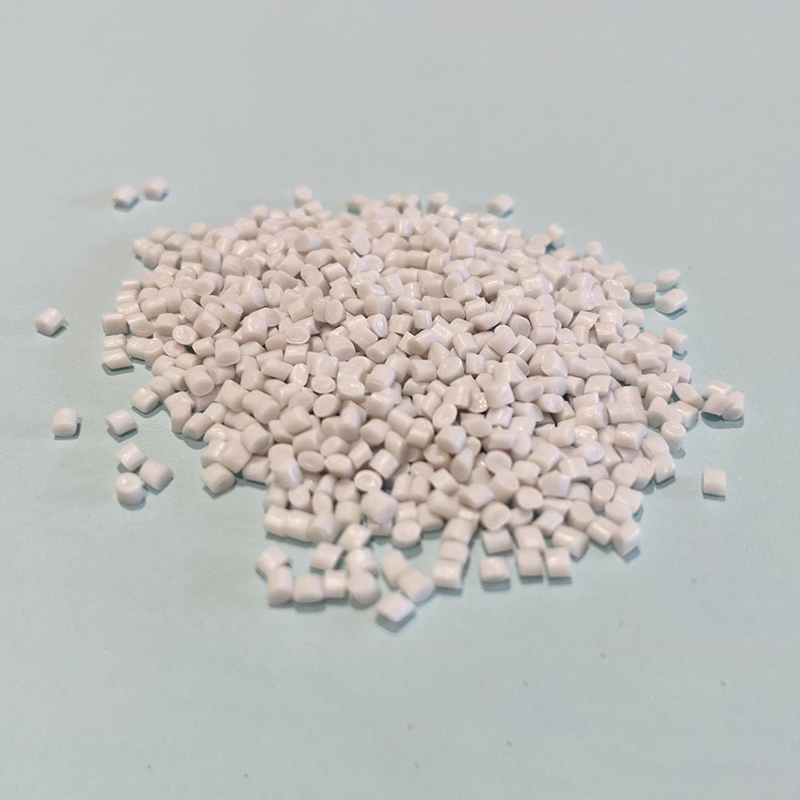

PET chemical aha Polyethylene terephthalate, makwaara dị ka polyester, chemical usoro COC6H4COOCH2CH2O.A kwadebere Dihydroxyethyl terephthalate site na transesterification nke dimethyl terephthalate na ethylene glycol ma ọ bụ esterification nke terephthalate na ethylene glycol, na mgbe ahụ mmeghachi omume polycondensation.Ọ bụ polyester jupụtara kristal, ọcha na-acha ọcha ma ọ bụ na-acha odo odo, polymer kristal nke ukwuu nwere elu dị larịị na nke na-egbuke egbuke.Ọ bụ resin a na-ahụkarị na ndụ, enwere ike kewaa ya na APET, RPET na PETG.

PET bụ mmiri ara ehi na-acha ọcha ma ọ bụ na-acha odo odo, nke nwere nnukwu kristal nke nwere elu dị larịị, na-egbuke egbuke.Ọ nwere magburu onwe anụ ahụ na n'ibu Njirimara na a dịgasị iche iche okpomọkụ nso, ogologo oge ojiji okpomọkụ ruo 120 ℃, magburu onwe eletriki mkpuchi, ọbụna na elu okpomọkụ na elu ugboro, ya eletriki Njirimara ka dị mma, ma ogbenye corona iguzogide, creep iguzogide, ike ọgwụgwụ, mgbochi esemokwu, nkwụsi ike akụkụ dị ezigbo mma.PET nwere njikọ ester, ire ere ga-eme n'okpuru omume nke acid siri ike, alkali siri ike na uzuoku mmiri, iguzogide ihe mgbaze organic, ezigbo ihu igwe.

2.resin Njirimara

PET nwere ezigbo nguzogide na-akpụ akpụ, nkwụsi ike ike ọgwụgwụ, mgbakasị esemokwu na nkwụsi ike akụkụ, obere iyi na ike siri ike, ma nwee nnukwu ike na thermoplastics: arụmọrụ mkpuchi ọkụ eletrik dị mma, obere mmetụta nke okpomọkụ, mana nguzogide corona adịghị mma.Ndị na-adịghị egbu egbu, nkwụsi ike ihu igwe, nkwụsi ike dị mma megide kemịkalụ, mmiri na-adịghị ala ala, iguzogide acid na-adịghị ike na ihe mgbaze organic, ma ọ bụghị ikpo ọkụ na-eguzogide mmiri, ọ bụghị nkwụsị alkali.

PET resinnwere nnukwu iko mgbanwe okpomọkụ, ngwa ngwa crystallization ọnụego, ogologo ịkpụzi okirikiri, ogologo ịkpụzi okirikiri, nnukwu ịkpụzi shrinkage, ogbenye akụkụ kwụsie ike, kenkuwa crystallization ịkpụzi, obere okpomọkụ na-eguzogide.

Site na nkwalite nke ndị na-emepụta ihe na-emepụta ihe na ihe ndị na-eme ka ihe na-eme ka ọ dịkwuo mma na nkwado eriri iko, PET nwere àgwà ndị a na mgbakwunye na njirimara PBT.

1. Thermal deformation okpomọkụ na ogologo oge ojiji okpomọkụ bụ ndị kasị elu na thermoplastic general engineering plastics.

2. N'ihi na elu okpomọkụ na-eguzogide, na enwekwukwa PET impregnated maka 10S na solder bath na 250 Celsius C, fọrọ nke nta na-enweghị deformation ma ọ bụ discoloration, nke bụ karịsịa kwesịrị ekwesị maka nkwadebe nke electronic na eletriki akụkụ maka solder ịgbado ọkụ.

3. The ekwe ike bụ 200MPa, na-agbanwe modulus bụ 4000MPa, na creep eguzogide na ike ọgwụgwụ dịkwa nnọọ mma, elu ike ike dị elu, na n'ibu Njirimara yiri thermosetting plastics.

4. Ebe ọ bụ na ọnụ ahịa ethylene glycol eji na-emepụta PET fọrọ nke nta ka ọ bụrụ ọkara nke butanediol nke a na-eji na-emepụta PBT, PET resin na agbakwunyere PET bụ ọnụ ala dị ala n'etiti plastik engineering ma nwee nnukwu ụgwọ ọrụ.

Iji meziwanye akụrụngwa PET, PET nwere ike iji PC, elastomer, PBT, klas PS, ABS, PA.

A na-ahazi PET (PET emelitere) nke ọma site na ịkpụzi injection, na ụzọ ndị ọzọ gụnyere extrusion, ịkpụ ịkpụzi, mkpuchi na ịgbado ọkụ, akara, igwe, mkpuchi agụụ na ụzọ nhazi nke abụọ ndị ọzọ.Kpọọ nke ọma tupu akpụ.

A na-akwado polyethylene terephthalate site na transesterification nke dimethyl terephthalate na ethylene glycol ma ọ bụ esterification nke terephthalate na ethylene glycol, na mgbe ahụ, mmeghachi omume polycondensation.Ọ bụ polyester juputara kristal, nkezi ịdị arọ molekụla (2-3) × 104, nha nke ịdị arọ na ọnụọgụ nke ịdị arọ molekụla bụ 1.5-1.8.

Glass mgbanwe okpomọkụ 80 ℃, Martin okpomọkụ eguzogide 80 ℃, thermal deformation okpomọkụ 98 ℃ (1.82MPa), decomposition okpomọkụ 353 ℃.Ọ nwere ezigbo n'ibu Njirimara.Nnukwu isi ike.Isi ike dị elu, obere ntinye mmiri, nkwụsi ike akụkụ dị mma.Isi ike dị mma, nguzogide mmetụta, nguzogide esemokwu, nguzogide na-akpụ akpụ.Ezigbo nguzogide kemịkalụ, soluble na cresol, sulfuric acid gbadoro anya, nitrobenzene, trichloroacetic acid, chlorophenol, insoluble na methanol, ethanol, acetone, alkane.Na-arụ ọrụ okpomọkụ -100 ~ 120 ℃.Ike na-ehulata 148-310MPa

Ntinye mmiri 0.06% -0.129%

Ike mmetụta 66.1-128J /m

Rockwell hardness M 90-95

Mgbatị 1.8%-2.7%

3. teknụzụ nhazi

PET nhazi nwere ike ịbụ injection ịkpụzi, extrusion, ịfụ ịkpụzi, mkpuchi, bonding, machining, electroplating, agụụ gold plating, obibi.Ihe na-esonụ na-ewebata ụdị abụọ.

1. Injection ogbo ① okpomọkụ ọnọdụ: nozzle: 280 ~ 295 ℃, n'ihu 270 ~ 275 ℃, n'etiti forging 265 ~ 275 ℃, mgbe 250-270 ℃;Ịghasa ọsọ 50 ~ 100rpm, ebu okpomọkụ 30 ~ 85 ℃, amorphous ebu bụ 70 ℃, azụ mgbali 5-15KG.② Trial dehumidification draya, ihe tube okpomọkụ 240 ~ 280 ℃, injection mgbali 500 ~ 1400 ℃, injection ịkpụzi okpomọkụ 260 ~ 280 ℃, ihicha okpomọkụ 120 ~ 140 ℃, were 2 ~ 5 awa.

2. Na fim ogbo, na PET resin na sliced na tupu akpọnwụwo iji gbochie hydrolysis, na mgbe ahụ amorphous oké mpempe akwụkwọ extruded na extruder na 280 Celsius C site na T-ebu, na jụrụ oyi drum ma ọ bụ coolant na-emenyụ. Debe ya n'ụdị amorphous maka ntụgharị uche.A na-agbatị mpempe akwụkwọ ahụ siri ike site na tent iji mepụta ihe nkiri PET.

Longitudinal ịgbatị bụ preheat na oké mpempe akwụkwọ ka 86 ~ 87 ℃, na na nke a okpomọkụ, gbatịa banyere 3 ugboro tinyere ndọtị direction nke oké mpempe akwụkwọ ụgbọelu, nke mere na nghazi ya nwere ike melite ogo crystallization iru a elu okpomọkụ: na transverse preheating okpomọkụ nke 98 ~ 100 ℃, na tensile okpomọkụ nke 100 ~ 120 ℃, na tensile ruru nke 2.5 ~ 4.0, na thermal ntọala okpomọkụ nke 230 ~ 240 ℃.Ihe nkiri ahụ mgbe ịgbatị kwụ ọtọ na kwụ ọtọ kwesịrị ịdị na-ekpo ọkụ iji kpochapụ nrụrụ ihe nkiri nke ịgbatị ahụ kpatara ma mee ihe nkiri nwere nkwụsi ike dị mma.

Oge nzipu: Sep-05-2023